Engaging

Embossing & Debossing

In this digital age we’re seeing an increase in sensory marketing as it creates more of a social than technological exchange. And research backs up the importance of physical. Over two-thirds (70%†) of people claim mail gives them a better impression of the company that sent it, while touch generates powerful and lasting emotions.

† Royal Mail MarketReach Physically Irresistible

Go convex, or concave!

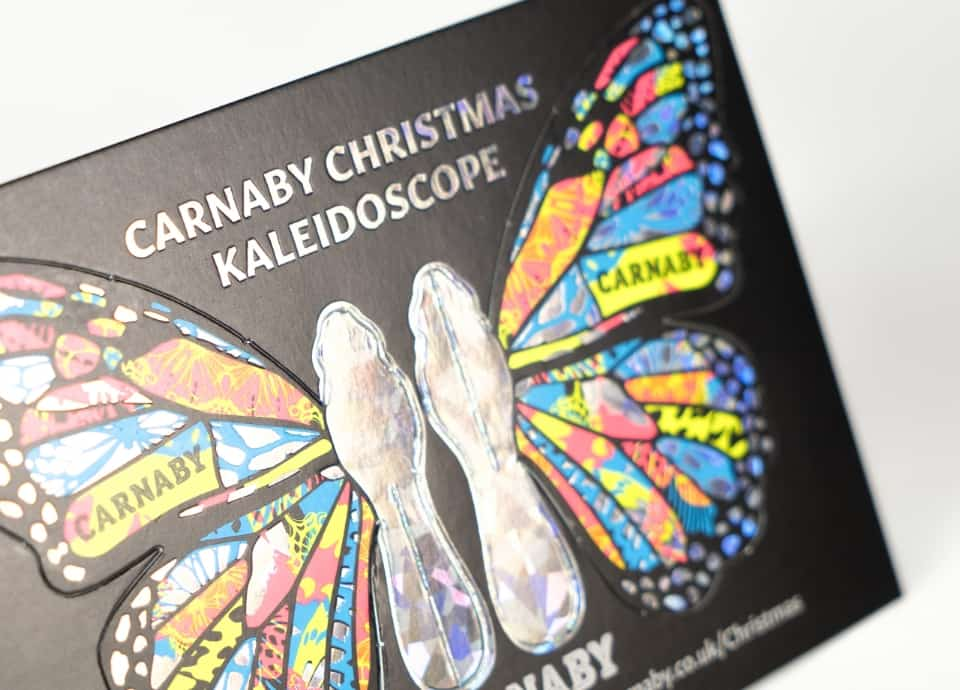

With embossing, we raise an image on paperboard whereas debossing produces an inverted, concave effect. Such processes are perfect for logos, crests or clever design work. Embossed print on packaging or labels can really inspire customers to pick up the item just to experience its texture, it also increases their value perception.

Both debossing and embossing add depth and stand-out to a print job, they also add an element of premiumisation, a high-end finish that appeals to both the eyes and hands.

We can emboss or deboss sheet sizes from SRA4 up to B1 on either our hand-fed or fully automated Bobst Speria

Choose from single level embossing to raise a border, for example, or multilevel for more sculptured images and stunning 3D effects

Spot UV varnished areas are highly suited to embossing

Learn more

Embossing

We achieve this effect by using a die and counterforce. As a technique it can also give additional prominence to foil finishing. We can do single level embossing as well as multilevel, where amazing 3D effects can be achieved.

Debossing

We use the same process to deboss as to emboss, it’s just that the image is recessed as opposed to raised. Debossed designs can be printed to accentuate the effect. With debossing, the reverse of the paperboard remains unaffected, unlike embossing, thus leaving both sides useable.

Embossing & debossing FAQs

What is a blind emboss?

A blind emboss uses no ink just the paperboard and is a far subtler effect whereas a registered emboss is aligned with a printed, varnished or foiled image.

What are the benefits to embossing and debossing?

They improve stand-out, they draw attention from both a visual and haptic perspective and they can increase the perceived value of your client’s products or services.

What depth can the impressions be?

It depends on the substrate really but generally embossing can lift images 15-25 microns.