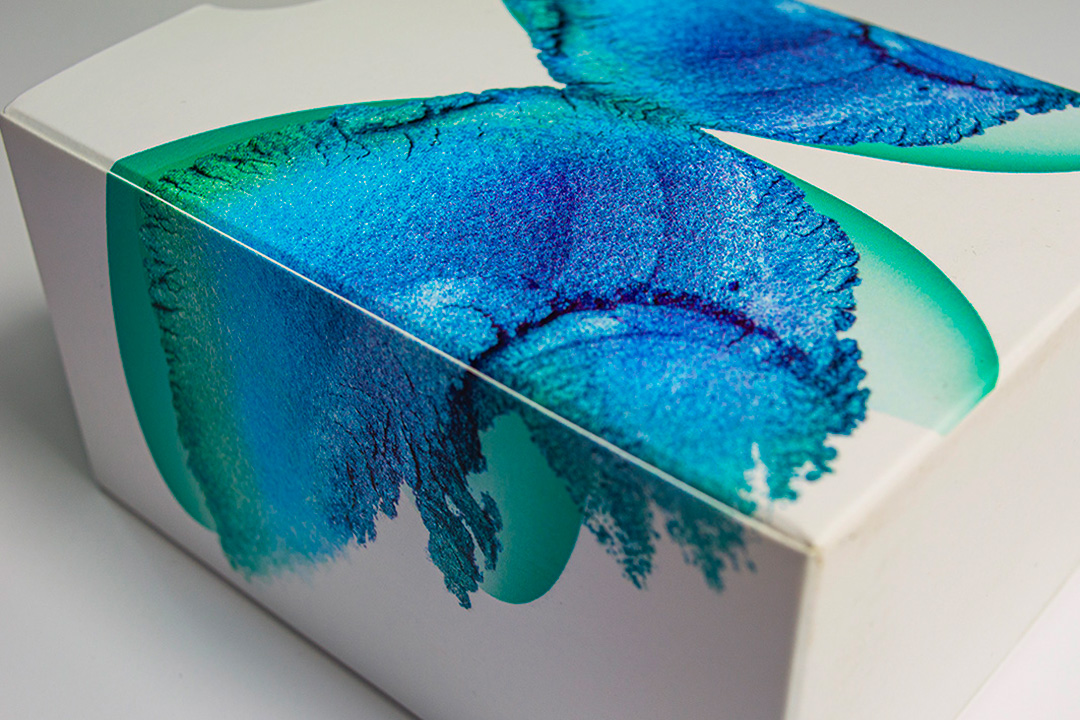

Clever carton

gluing

Packaging is yet another means for brands to connect with their customers in new and different ways. But whether the carton is designed to be hedonistic, utilitarian or recyclable, it still has to offer protection during storage and distribution, and withstand handling and potential display, and much of this relies on how well it is glued together.

Stick with us!

We have two folder-gluer machines to give us the flexibility to produce different blank and folded sizes. Both can use either hot or cold glue to transform cartons ready for fulfilment. The die-cuts and creased blanks pass through adhesive systems before pressure is applied to cure the glue.

We can produce straight line, reverse tuck end (RTE), straight tuck end (STE) and crashlock bottom cartons as well as double wall trays

Both folder-gluers use hot or cold glue to produce cartons in box board or micro flute materials

Blank sizes need to be a minimum of 60mm x 50mm and maximum of 900mm x 800mm.

Custom Gluing FAQ

What material is best for manufacturing cartons?

We suggest using folding box board (FBB) or solid bleached sulphate board (SBS) to achieve the best results.

What thickness of board is best?

All depending on the carton style and its intended purpose, we suggest 400 microns or more.

Which is best for adhesion, hot or cold glue?

It largely depends on the application of the carton and whether it will be exposed to changes in environmental conditions during transportation, storage and usage. We process using hot and cold glue and are team would be pleased to advise on the best solution.

“When we have a prestigious job for finishing OLRO is the first company we contact.”